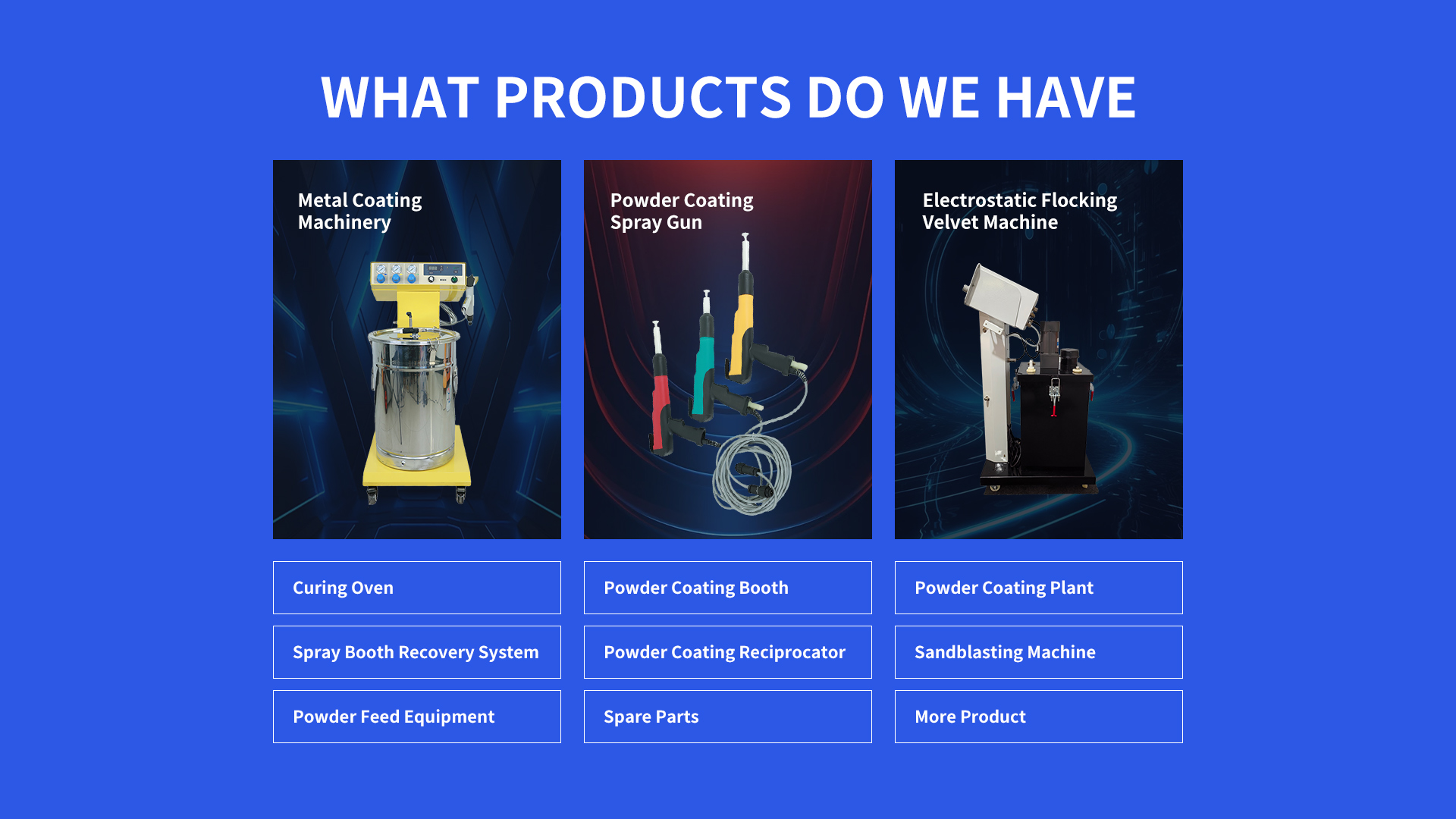

1. Powder Coating Spray System: Equipment Introduction and StructureA Powder Coating Spray System is an essential tool for achieving a high-quality finish on various materials. It primarily comprises a powder supply unit that stores the powder coating, an electrostatic powder gun that charges and sprays the powder, and a powder recovery system. The electrostatic generator within the system gives the powder particles an electrical charge, enabling them to adhere to the grounded object being coated.

2. Application Scenarios of Powder Coating Spray System

These systems have diverse applications. In the manufacturing of metal products like appliances, powder coating spray systems are used to provide a durable and aesthetically pleasing finish. In the aerospace industry, they help protect components from corrosion and wear. Additionally, they are widely employed in the production of outdoor furniture to ensure resistance to harsh weather conditions.

3. Price Range of Powder Coating Spray System EquipmentThe cost of a

Powder Coating Spray System can vary significantly. Basic models suitable for small-scale applications may cost a few hundred dollars. More advanced systems with features such as automated controls, high-efficiency powder recovery, and precise electrostatic charging can range from a few thousand to tens of thousands of dollars, depending on the brand and specifications.

4. Correct Usage of Powder Coating Spray System Equipment

To use the system correctly, first, prepare the surface by cleaning and degreasing it thoroughly. Adjust the powder flow rate and electrostatic voltage according to the coating requirements. Hold the powder gun at a consistent distance (usually 6-10 inches) from the surface and move it in a smooth, overlapping motion. After spraying, cure the coated item in an oven at the appropriate temperature and time as per the powder manufacturer's instructions.

5. How to Select Powder Coating Spray System EquipmentWhen choosing a

Powder Coating Spray System, consider the volume of work. For high-volume production, a system with a large powder hopper and high spraying capacity is necessary. Also, look for a system with a reliable electrostatic generator for consistent coating quality. An efficient powder recovery system is crucial to minimize waste and reduce costs.

6. Safety Precautions for Powder Coating Spray System EquipmentSafety is paramount when operating a

Powder Coating Spray System. Wear appropriate personal protective equipment, including a respirator, safety glasses, and gloves. Ensure the work area is well-ventilated to prevent the accumulation of powder dust, which can be explosive. Keep flammable materials away from the system and regularly check for any electrical or mechanical faults.

7. Rationality Analysis of Powder Coating Spray System EquipmentPowder Coating Spray Systems are a rational choice due to their environmental benefits. They produce less waste compared to liquid coating methods as the oversprayed powder can be recovered and reused. They also offer a thicker and more uniform coating, resulting in better protection and longer-lasting finishes, making them cost-effective in the long term.

8. Q&A about Powder Coating Spray System Equipment

Q: What affects the coating quality of a powder coating spray system?

A: Factors like the powder flow rate, electrostatic voltage, gun-to-surface distance, and surface preparation all impact the coating quality.

Q: Can I use different brands of powder in my system?

A: It's best to check the system's compatibility with different powder brands. Some systems may work better with specific types of powder.

Q: How often should I maintain my powder coating spray system?

A: Regular maintenance, such as cleaning the powder gun, checking the electrostatic generator, and maintaining the powder recovery system, should be done based on usage frequency, but at least once a month.

Q: What is the advantage of an electrostatic powder gun in the system?

A: The electrostatic powder gun charges the powder particles, allowing them to adhere more effectively to the surface, resulting in a more even and efficient coating.

Q: Are there any limitations to the materials I can coat with a powder coating spray system?

A: While it can coat many materials like metals, some plastics, and wood with proper preparation, extremely heat-sensitive materials may pose challenges due to the curing process.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com